Available materials: EPDM, silicone rubber, neoprene, thermoplastic EPDM

Optional standards: National standard, American standard, British standard, German standard, European standard

Specifications: Custom sizes accepted

SILICONE rubber sealing strip

Silicone rubber sealing strips have excellent high-temperature resistance and thermal oxidation aging resistance. The sealing strips produced from mountain silicone rubber are aesthetically pleasing, highly decorative, and available in various colors such as gold, silver, tea, and green, which can be adjusted according to the door frame color. They are compatible with silicone adhesives and are recognized as the best sealing material.

EPDM rubber sealing strip

EPDM rubber sealing strips have extremely high chemical stability, excellent ozone resistance, weather resistance, and thermal aging performance. They can be used for a long time in sunny and humid natural environments without cracking under intense sunlight, maintaining good elasticity, high elongation, and high strength. They are currently the most widely used sealing material.

Soft PVC sealing strip

PVC has been widely used in curtain walls for its cost-effectiveness, but its thermal aging performance is inferior to other rubbers and thermoplastic materials. Our company has adjusted the formula to not only improve its thermal aging performance but also produce soft and robust PVC sealing strips according to the structural requirements of glass curtain walls.

Soft PVC sealing strip

NEOPRENE rubber sealing strip

Neoprene rubber sealing strips have high weather resistance and ozone aging resistance, outstanding flame resistance, heat resistance, corrosion resistance, and oil resistance. When exposed to fire, they only carbonize without continuing to burn, and they have good self-extinguishing properties. They are the best flame-retardant rubber sealing material among high-elasticity rubbers, with characteristics of low deformation and no cracking during long-term use.

Thermoplastic EPDM strip (TPV)

Thermoplastic EPDM (TPV) is a third-generation environmentally friendly sealing material, with basic physical properties between silicone rubber and vulcanized EPDM rubber. It can be reused without pollution and is compatible with silicone adhesives, serving as an economical alternative to silicone rubber. Its most significant feature is the ability to be freely welded on-site. Its unique shaping processing advantages also allow for the creation of precise, complex, and composite structures that are difficult to achieve with other sealing materials. The specific gravity of thermoplastic EPDM rubber is the lightest among all sealing materials, with a typical value of only 0.98g/cm³. For the same weight, the length of sealing strips made from it is the longest, thus providing good economic value. Thermoplastic EPDM materials (TPV) are one of the trends in the development of sealing materials!

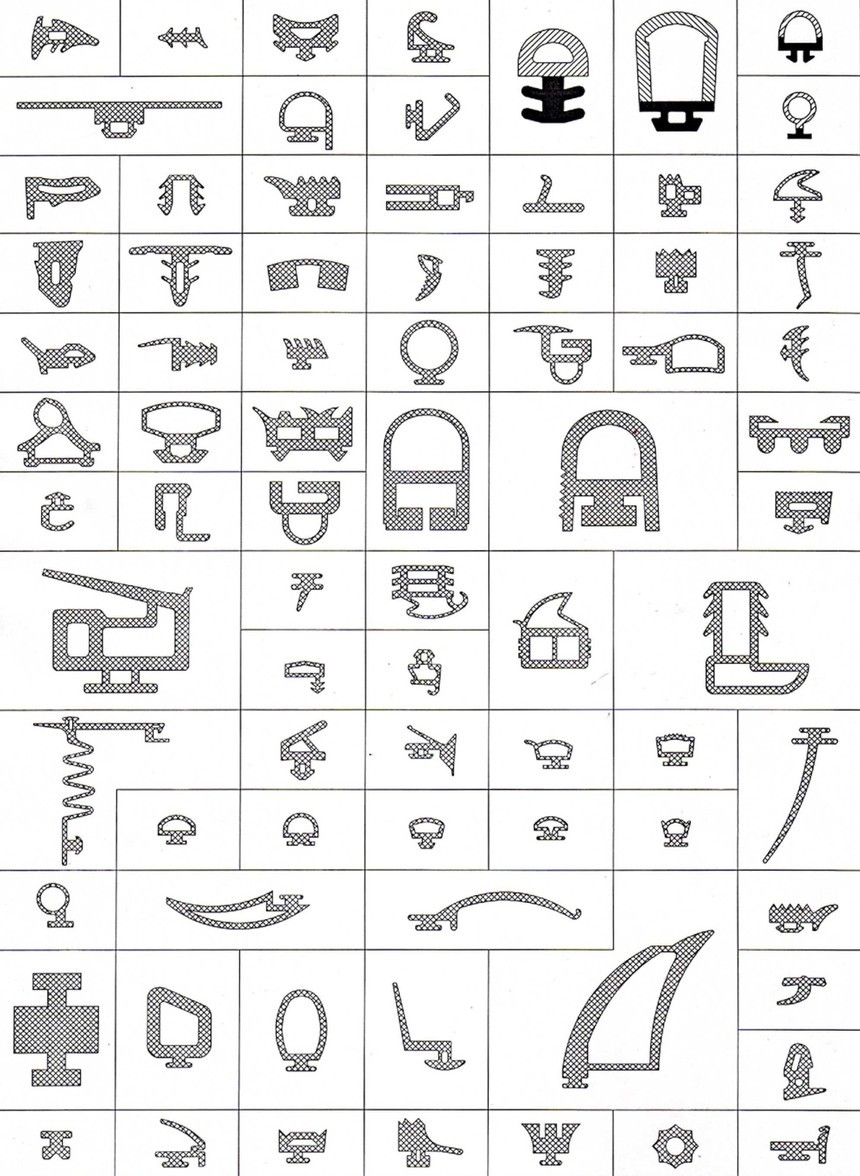

Some sealing strip patterns